Circularity

Projects

Impact Fellow/Core

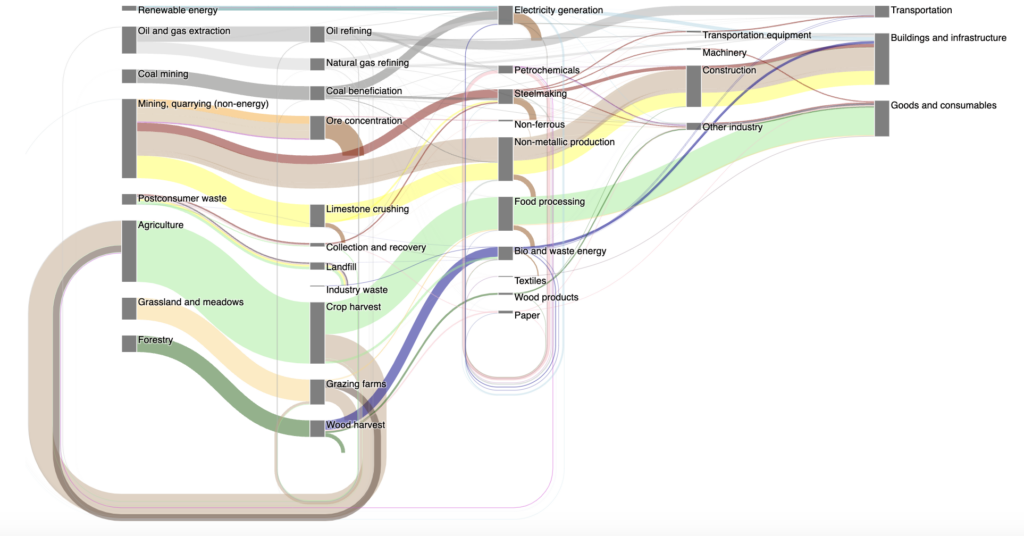

- Perspective on cross-industry circularity challenges (Maji)

- Common barriers to circularity transitions across industry sectors and opportunities for collaboration

- Circularity Dashboard: Linking circularity to sustainability (Maji)

- Digital dashboard establishing qualitative and quantitative relationships between circularity and sustainability that are comparable across material streams, and developing pathways to estimate impacts

Seed

2024

- Reducing embodied carbon at work: Low-carbon cement-based product strategies for data centers, warehouses, and industry (Kirchain)

- This proposal will provide the knowledge and tools for MCSC members to benchmark their current construction-related embodied carbon status, understand the existing and emerging strategies to reduce that carbon, and to identify the scalable low-carbon cement-based product solutions most suited to their application and context. This proposed work will explore strategies to reduce the carbon burden of both buildings and horizontal construction (e.g., parking facilities and courtyards).

- Employing AI to sort plastic waste by manufacturer (Olsen)

- This project will use branding marks on packaging to effectively sort plastics by manufacturer type instead of plastic type using AI image recognition. This workflow is well-suited for Extended Producer Responsibility (EPR) which places the onus of packaging recyclability on the producer or manufacturer and presents a potentially more effective and palatable alternative to the general plastic production taxes or bans being implemented in jurisdictions today. Because this technology could also be readily implemented with modest modifications to current system operations and without system-wide collective agreement on change, it presents an extremely promising approach for near-term action to improve circularity.

2022

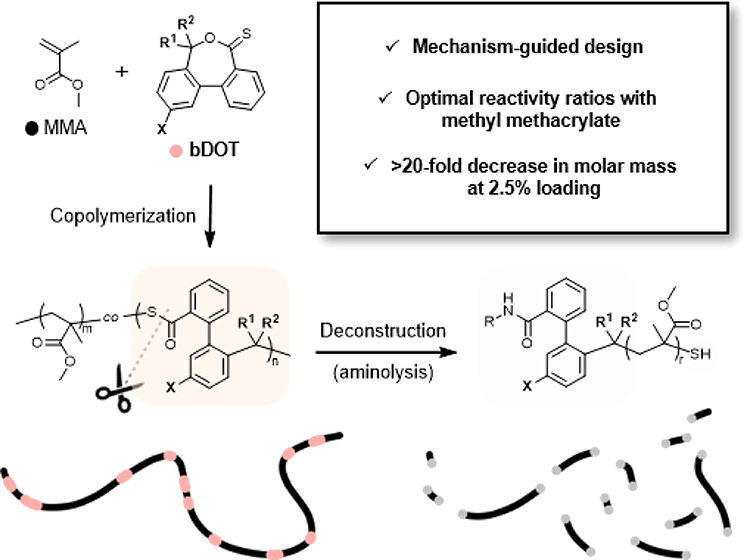

- Cleavable comonomers for sustainable vinylic thermosets (Johnson)

- End-of-life options for vinylic thermosets are limited to accumulation in landfills or energy- and emission-intensive incineration, accelerating both the climate and global plastic waste crises. This project aims to develop a strategy to render these materials deconstructable and recyclable without compromising their useful physical properties.

-

Seed Award Summary

- Engineering of a microbial consortium to degrade and valorize plastic waste (Cordero)

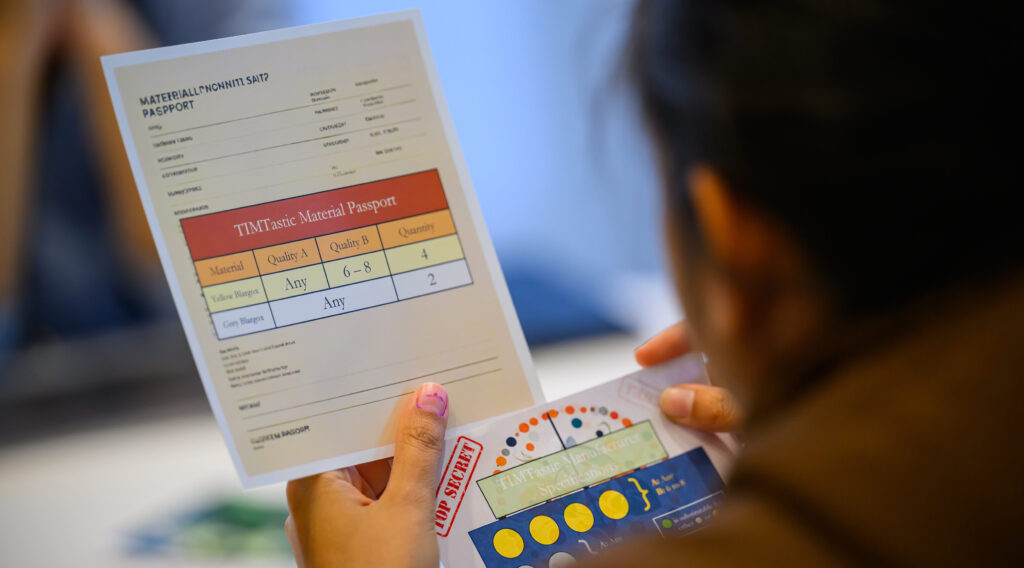

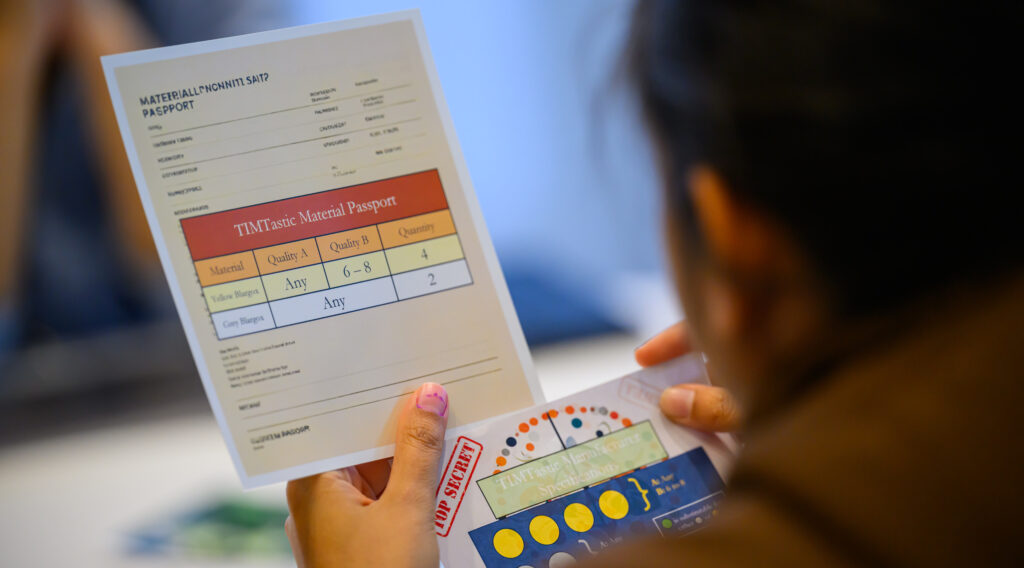

- In this work, the team will engineer a synthetic microbiome based on marine microbes that degrade bio-based polymers used for packaging – exploring the interaction mechanisms between microorganisms in a 7-8 species consortium and their impact on degradation rates and chemical degradation products. After characterizing the consortium and identifying its optimal composition, they will propose a pilot-scale reactor to demonstrate the feasibility of this concept as a novel waste management strategy that enables the recovery and recycling of biodegradable plastics.

-

Seed Award Summary

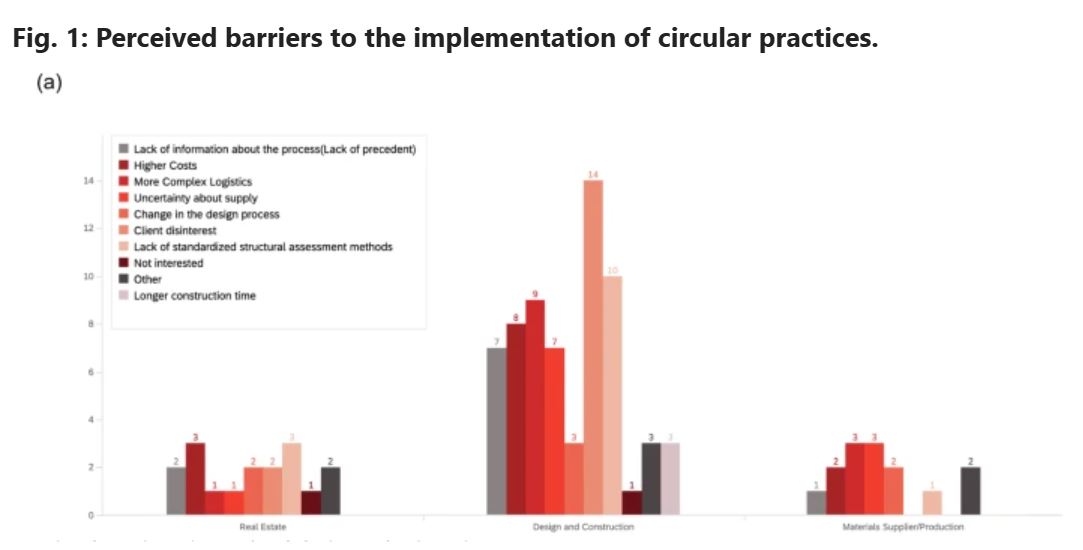

- The costs and benefits of circularity in building construction (Zheng)

- This project aims to characterize the barriers and opportunities for increased circularity of building materials and develop a preliminary roadmap to overcome those barriers for construction materials. They will survey 500 members of at least one large state building association to assess their current circular practices, their attitudes towards, beliefs about, and experiences with circular building practices. Its output will be used for an academic publication, and white paper(s) to engage industry members and policy makers.

-

Seed Award Summary

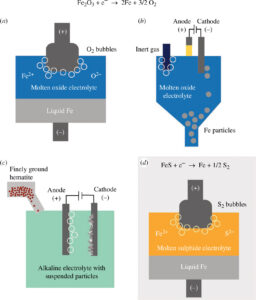

- Colorimetric sulfidation for aluminum recycling (Allanore)

- This team has developed a new, cost-effective sulfidation technology that is particularly suited to treat typical pigments and impurities found in aluminum scrap mixed that are currently landfilled. They will evaluate the technical and economical feasibility of using the new sulfidation technology to process and sort aluminum scraps that today are either difficult to distinguish, or that are simply landfilled due to their unfavorable coatings.

-

Seed Award Summary

- Short-term and long-term efficiency gains in reverse supply chains (Sheffi)

- This study focuses on the recovery and recycling system for the municipal solid waste, which is currently affected by numerous inefficiencies: underserved communities because of the extant coverage of the processing facilities, high cost of transportation and high environmental impact. The research project will prototype a series of quantitative models which allow the assessment the comparative performance of competing models for reverse logistics.

-

Seed Award Summary

- Design innovation in reconfigurable concrete structural systems (Mueller)

- A product called Pixelframe is being developed which has lower embodied emissions than traditional pour concrete, and is modular and can be re-used for multiple building lifetimes.

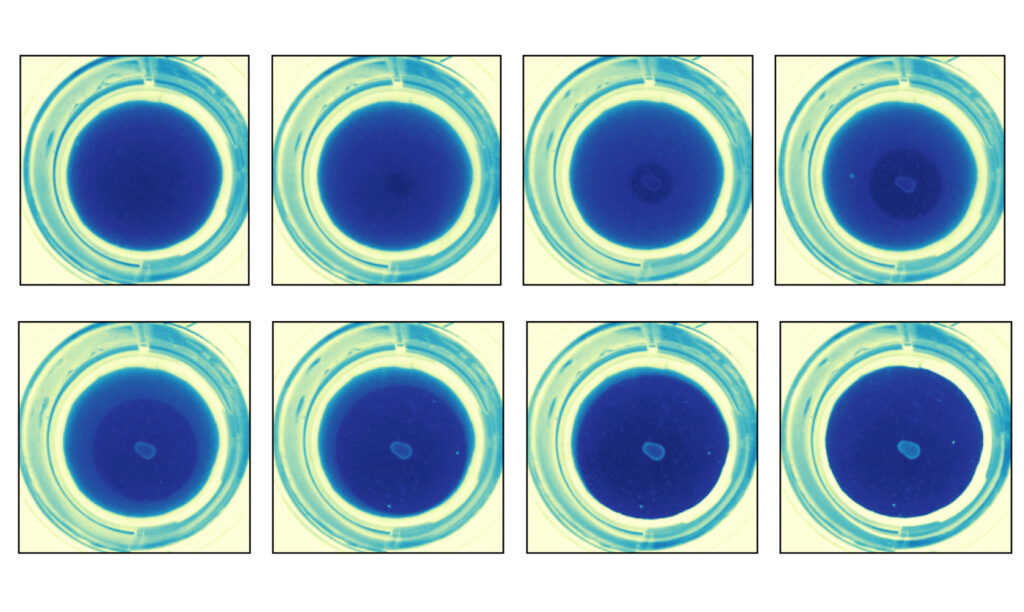

- Generalizing the high-throughput clearzone assay beyond polyester biodegradation (Olsen)

- The development of biodegradable polymers remains limited by current biodegradation testing methods. To address this limitation, this project has developed an expansive biodegradation dataset to help determine whether or not a polymer is biodegradable.

- Double loop circularity in materials design demonstrated on polyurethanes (Olsen)

- This team will develop materials for a new double loop circularity paradigm whereby biomass-based polymers are designed to be mechanically recycled when they are collected but biodegraded when they are accidentally released, providing a high carbon-efficiency and environmentally robust solution to plastics sustainability. We will demonstrate this new paradigm on polyurethanes of potential interest as interlayer adhesives in multilayer packaging, a large sustainability challenge due to its lack of biodegradation and incompatibility with most current and proposed recycling processes.

- High throughput screening of sustainable polyesters for fibers (Rutledge)

- In this project, the team will develop high throughput screening techniques suitable for the rapid evaluation and identification of candidate polyesters that are synthesizable, spinnable, meet the performance profiles of existing synthetic and/or natural fibers, and degradable. They will collect data on two polyester families, the poly(3-hydroxyalkanoates) and polyesters based on furan dicarboxylic acid. From the data collected, they will develop quantitative structure-property relationships to predict the properties of polyesters yet to be synthesized.

- Fruit-peel-inspired, biodegradable packaging platform with multifunctional barrier properties (Varanasi)

- This team aims to establish a framework which will allow the design of low-cost sustainable packing with high flexibility in mechanical characteristics, barrier properties as well as fabrication methods. Based on this framework, they will develop coatings to enhance barrier properties of existing biodegradable packaging, such as paper cups, as well as stand-alone packaging materials.

Contact Us

Get in touch with the MCSC

If you would like more information, please e-mail mcsc@mit.edu.

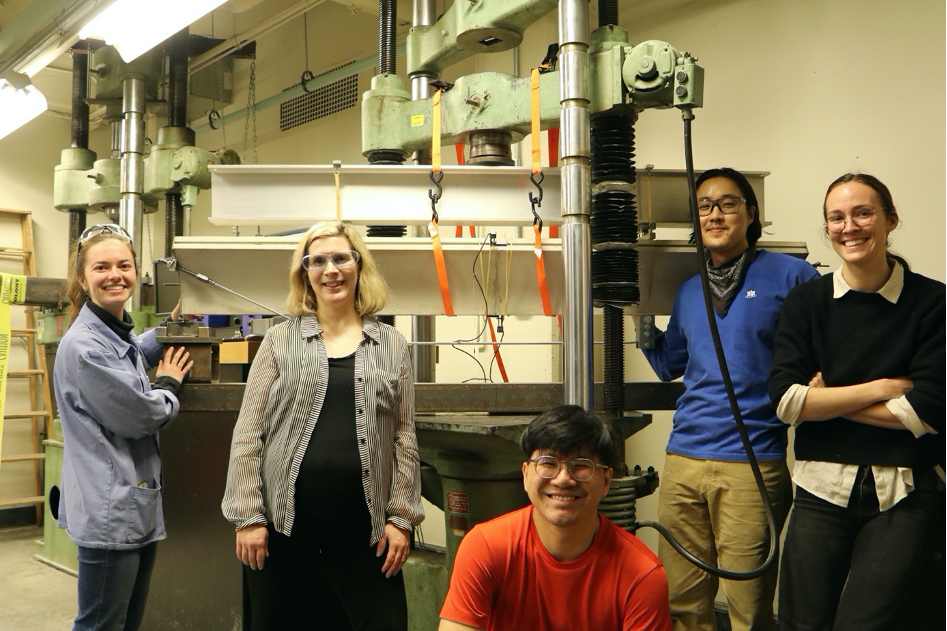

Who's studying this

MCSC Impact Fellow